![]()

When we develop workwear and safety footwear you and your industry are always in focus. And when we say that our product is TESTED TO WORK, we are not just making up a catchy slogan – it is our most important value and the core of everything we work with.

For you, TESTED TO WORK is a guarantee that your MASCOT products are thoroughly tested before you get your hands on them. This means that you are guaranteed very durable and functional products, where nothing is left to chance.

Your favourite workwear needs to last

Our ambition is to produce your new favourite workwear. The clothes you want to wear time and time again, and which always meet your needs for function and comfort. Naturally, your favourite workwear needs to be of the highest quality and produced responsibly.

By that we mean that workwear production is characterised by efficient resource usage and the lowest possible levels of waste and emissions as a result. And of course it needs to stand the test of time. Our goal is that every single product becomes your favourite workwear, which will be used the most and for the longest time possible. This is why TESTED TO WORK is so important to us!

Long-lasting products are responsible products

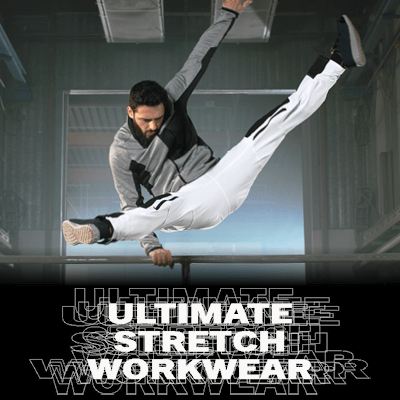

A comprehensive development process is behind every quality product introduced on the market. Every single product and type of material is the result of many months of development during which we optimise the properties that are important to your needs. High wear resistance, low material weight and, for example, ULTIMATE STRETCH are some of the properties that we focus on incorporating into our products.

Tests, tests and yet more tests

MASCOT's experienced textile experts test the material types and then constantly fine-tune them, and we continue testing between each stage of development. In part, this takes place in our large network of test subjects composed of tradespeople specialising in different areas – and we are never satisfied until our test subjects are happy with our products.

In addition, we perform extensive laboratory tests and quality control in our own laboratory, where we have machines that perform standard tests in accordance with many different European standards, including wear resistance, tear resistance, water resistance and breathability. The constant hunt for the best material properties means that you gain access to unique fabric types that are not available elsewhere.

Long durability minimises overall resource consumption

When you buy workwear from MASCOT, you get extra value for money. All of our products have been tested at our test centre and in accordance with our TESTED TO WORK principles. This results in very durable and long-lasting products, which is not just good for your work and wallet, but also for the environment, as it means there is a reduced need to produce new workwear.

Clothes – no matter their brand – have a huge climate footprint. They require a large number of raw materials (for example, polyester is made from fossil fuels and cotton takes a lot of water to grow) and a lot of energy is used in dyeing, transporting and manufacturing them.

Therefore it is important that the clothes which are actually produced are used for as long a time as possible, as it is the manufacturing phase in particular that uses large amounts of energy. The longer an item of clothing lasts, the longer before this heavy process with its high levels of energy consumption needs to be undertaken again. In other words: The total carbon footprint of your workwear diminishes significantly over time because the clothing lasts longer.

Our TESTED TO WORK strategy is an important part of the reduced climate impact our products have. All of our fabrics are selected for particular use situations and tested to be able to withstand the wear that workwear is typically subjected to.